Heavy duty ultrasonic anti fouling in the best Dutch maritime engineering tradition

Shipsonic™ has chosen a robust, industrial approach to its systems designs. Ships are 24-7 on the move. In the engine rooms, humidity and temperatures can be very high for extended periods. On the high seas, you cannot call a service engineer to check on problems with one of your ship’s systems. Therefore Shipsonic™ systems are purely functional, no-frills such as digital displays or wireless system monitoring. All such frivolities may look nice on a trade show, but they tend to break down, making your system vulnerable. We are not concerned with cosmetics, but with reliability.

We are one of the few, if not the only ones, who work with 80, 100, or even 120Watt transducers. This results in more ultrasonic energy in the object you want to protect, but the heavier transducers also have a lower resonance frequency. It is known that the lower frequencies of the ultrasonic spectrum are more efficient.

Resonant frequencies (the resulting frequency after installation) fluctuate with the kind of object and method of installation. Our design features a standalone software module for each transducer, running through all relevant frequencies, which enables us to ensure that each transducer is optimally powered. This means every transducer always receives pulses in its own, specific resonance frequency.

The Shipsonic electronics engineer has made a deliberate design effort to guarantee that the transducers in our systems can be powered continuously without excessive heat generation. The life cycle of electronics is severely shortened by excessive heat or fluctuating temperatures. Our system design ensures that all electronics always stay at least 25% below their maximum temperature specifications. except for the HDS10 and the HDS20, all control units are equipped with 2 cooling fans, one blowing inward and one blowing outward to guarantee proper air circulation inside.

In the Shipsonic design, each transducer is a stand-alone module, with a separate power supply, separate power circuit board (PCB), and separate software module. This means that if one transducer fails, all other transducers of the same control unit will continue to function. In the case of a short circuit in the transducer cable, the electronics can be damaged. But since the PCBs in the control unit are plug-and-play; replacing a PCB requires no special knowledge and requires 5 minutes, even on the high seas!

On request, Shipsonic offers adaptations to our systems, as the client wishes. Most frequently, we offer the following: CANBUS connection; for system monitoring in the chief engineers’ quarters PLC (programmable logic controller); to control a large number of transducers from one point, eg sluice gates or similar large objects

A system consists of a control unit with connections for 1, 2, 4, 6 or 8, 12, 16, or 20 transducers. All systems can be delivered functioning on 240 VAC or 24 VDC. Or auto-switching combinations of these. The systems for 12, 16, or 20 transducers can function on 240 VAC or 400 VAC. Systems for 1 or 2 transducers are also available on 12 VDC. Altogether we have 21 different models.

Shipsonic or one of our agents will help you with the optimal configuration of your system. This configuration depends on the type and size of the object (sea-chest, box-cooler, bucket-strainer, hull, etc). We often place different transducer types on 1 object, to guarantee a wide spectrum of ultrasonic frequencies.Thus, control units and transducers are sold separately, according to individual system designs. Our Power Circuit Boards (PCBs) can also be supplied independently.

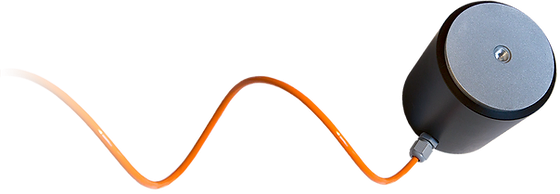

Shipsonic offers 3 different types of transducer

80 Watt 23 kHz, IP67 or IP68 This transducer is exceptionally small given its power and response frequency. That makes this model especially apt for installation on box coolers, where installation space is often confined.

100 Watt 28 kHz, IP67 or IP68 The 100Watt, 28kHz is our most used model. Very apt for installation on piping

120 Watt 20 kHz, IP67 or IP68 A heavy hitter, 120 Watt! Very good for application on thick walls of sea chests and hulls.

Transducers are directly glued to the object, optimizing energy transfer. All models can also be used with an aluminum installation adaptor. The adaptor can be machined in the same curve as e.g. piping or a bucket strainer on which the transducer is to be installed.